Structural and thermal behavior of proclay kaolinite using

2015.2.1 The XRD pattern of the proclay samples obtained by high energy ball mill for more than 3 h is similar to the patterns of a metakaolinite obtained by thermal calcination.

consulter en ligne

Kaolin vertical roller mill_PRODUCT_Tongli Machinery

A kaolin vertical roller mill is a specialized equipment used for grinding and processing kaolin into kaolin powder.Kaolin is a non-metallic mineral. It is a kind of clay and clay rock

consulter en ligne

Surface modification of calcined kaolin with toluene

2013.11.1 Abstract. The surface of calcined kaolin particle was modified with toluene diisocyanate (TDI) by using high energy ball milling. The prepared hybrids were

consulter en ligne

Preparation of potassium oleate-kaolin/natural rubber

2023.9.1 The ball milling promotes the chemical modification of kaolin by potassium oleate. • The gas-phase spray drying technology breaks the filler aggregates. • The gas

consulter en ligne

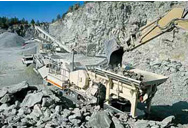

Kaolin Processing Plant Machinery-SBM Industrial

2023.1.3 Compared with the combined grinding system of traditional Raymond mill and ball mill, vertical roller mill has the advantages of large output, wide adaptability,

consulter en ligne

Effect of solid/ball ratio and grinding time on the mechanical ...

2023.11.23 In this study, the effects of solid/ball ratio and grinding time on the mechanical activation of kaolin were investigated. Samples with 10 µm particle size were

consulter en ligne

Kaolin Vertical Grinder, Energy-Saving Ball Mill, Factory

2024.1.1 Kaolin Vertical Grinder, Energy-Saving Ball Mill, Factory Grinding Equipment, Find Details and Price about Machine Milling Machine from Kaolin Vertical

consulter en ligne

Ball Mill Rotary Kiln Vertical Roller Mill Manufacturer - Tongli

Lepidolite/Spodumene vertical roller mill. Dolomite vertical roller mill. Kaolin vertical roller mill

consulter en ligne

(a) High energy milling machine, (b) planetary ball

Kaolin particles were pulverized in order to reduce the size by using high-energy ball milling under various ball-to-powder weight ratios.

consulter en ligne

Kaolin mill - All industrial manufacturers - DirectIndustry

Find your kaolin mill easily amongst the 18 products from the leading brands (Liming, ...) on DirectIndustry, the industry specialist for your professional purchases.

consulter en ligne

Kaolin rotary dryer_Rotary Dryer_PRODUCT_Tongli Machinery - ball-mills

Girth Gear:The rotary dryer girth gear is a large gear ring encircling the dryer, usually mounted on the dryer shell.It is driven by a pinion gear, and together they form the primary drive unit to rotate the dryer. Under the girth gear is the spring plate, the function of the spring plate is to reduce heat transfer from the shell to the girth gear to prolong the

consulter en ligne

China Ball Mill, Ball Mill Wholesale, Manufacturers,

China Ball Mill wholesale - Select 2024 high quality Ball Mill products in best price from certified Chinese Plastic Machinery manufacturers, Milling Machine suppliers, wholesalers and factory on Made-in-China ...

consulter en ligne

Kaolin vertical roller mill_Vertical roller mill_PRODUCT_Tongli

A kaolin vertical roller mill is a specialized equipment used for grinding and processing kaolin into kaolin powder.Kaolin is a non-metallic mineral. It is a kind of clay and clay rock mainly composed ... Ball mill grinding media. Vertical roller mill grinding roller wheel hub. Rotary kiln shell. Vertical roller mill grinding roller tyre.

consulter en ligne

Grinding Kaolin Clay? Now Is the Time to Know the Best Way

2023.2.15 Vertical structure, solid system, and stable performance. 2 Durable. The grinding roller and grinding ring have a long renewal cycle and long service life. ... The kaolin ball mill grinds kaolinite minerals into fine powder. Features: Price: $5,000 / set (minimum price) Maximum feed size: ≤25mm Production capacity: 0.65-615t/h Finished ...

consulter en ligne

What is a vertical roller mill (VRM)? A Comprehensive Guide

2023.10.3 Founded in 1958 Zhejiang Tongli Heavy Machinery Co., Ltd is an equipment manufacturer very famous in China domestic market for making ball mill, vertical roller mill, rotary kiln and all sorts of cement fertilizer production equipment, even though not as famous as FL Smidth, but Tongli is constantly improving to provide top-tier product

consulter en ligne

Energy Use of Fine Grinding in Mineral Processing

2013.12.18 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor. While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s

consulter en ligne

About Zenith - Grinding Mill, Grinder, Mills for Sale

Shanghai Zenith Mining and Construction Machinery Co., Ltd. is a hi-tech, engineering group. We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices. Our products approximately have been sold to 120 countries and areas, such as Southeast ...

consulter en ligne

Stirred Mill SpringerLink

2023.5.18 The vertical stirred mill is vertically installed, and gravity works in the grinding process. With the advantages of high grinding efficiency and less area occupation, it is widely used in the regrinding, fine grinding, and ultrafine grinding process of such metal mines as iron ore, copper ore, lead-zinc, and such nonmetallic mineral industries as

consulter en ligne

Effect of grinding media properties and stirrer tip speed on

2021.4.1 For example, the stirrer tip speed of the screw-type vertical stirred mill is approximately 3 m/s [19], whereas it is greater than 15 m/s for the IsaMill [20]. ... The liberation effect of magnetite fine ground by vertical stirred mill and ball mill. Miner. Eng., 34 (7) (2012), pp. 63-69. View PDF View article View in Scopus Google Scholar [4]

consulter en ligne

Kaolin Processing Plant Machinery - sbmchina

2022.12.30 Compared with the combined grinding system of traditional Raymond mill and ball mill, vertical roller mill has the advantages of large output, wide adaptability, simple operation, rapid adjustment, low use and maintenance cost, energy saving, etc., and is the preferred choice for deep processing of kaolin. Raymond mill for kaolin processing

consulter en ligne

Catalytic pyrolysis of waste polypropylene using low-cost

2023.7.20 Kaolin has the lowest cost of oil production compared to Hematite and white sand, which is 0.28 $/kg of oil. ... to a fine powder using a ball mill for 5 h, so that the grain size of the final ...

consulter en ligne

Kaolin vertical roller mill_PRODUCT_Tongli Machinery

A kaolin vertical roller mill is a specialized equipment used for grinding and processing kaolin into kaolin powder.Kaolin is a non-metallic mineral. It is a kind of clay and clay rock mainly composed ... Ball mill grinding media. Vertical roller mill grinding roller wheel hub. Rotary kiln shell. Vertical roller mill grinding roller tyre.

consulter en ligne

Kaolin rotary kiln_Rotary Kiln_PRODUCT_Tongli Machinery - ball-mills

Vertical Roller Mill (VRM): The vertical roller mill is a grinding machine that grinds materials into fine powders, after the raw material is crushed by the crusher, it enters the vertical roller mill. It is typically used for grinding raw materials, clinker, and additives in the cement manufacturing process.

consulter en ligne

How to choose between ball mill and vertical roller mill?

2022.6.24 The vertical mill has high grinding efficiency and low energy consumption, and the power consumption is only 40%-50% of the ball mill. 7. Finished product quality. Compared with the ball mill, the product of the vertical mill has a higher degree of homogenization and higher purity.

consulter en ligne

Ball mill, Ball grinding mill - All industrial manufacturers

ball grinding mill Ф2200×5500. horizontal for ore for cement. Final grain size: 74 µm - 400 µm. Rotational speed: 21 rpm. Output: 10 t/h - 20 t/h. Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed.

consulter en ligne

Industrial mineral powder production in China - ScienceDirect

2007.12.1 The annual production of ultra-fine kaolin clay from kaolin-rich coal resources has been on the increase with considerable reduction in investment due to the use of large scale stirred bead mills and direct gas flame rotary kilns, e.g., RMB 45 million for a 10,000 t/year plant during 1994–2004 and RMB 46 million in 2006 for the 30,000 t/year ...

consulter en ligne

Granulated blast furnace slag vertical roller mill_Vertical roller mill ...

Grinding Rollers: Grinding roller is the main part for crushing and grinding materials.The grinding roller is composed of cast steel roller sleeve, forging shaft and wear-resistant surfacing bushing. The grinding roller is installed on the rocker arm of the granulated blast furnace slag vertical roller mill, under the action of external force, it is pressed tightly on

consulter en ligne

Kaolin Processing Plant Machinery - LinkedIn

2023.3.23 Raymond mill for kaolin processing. Raymond mill is also frequent used grinding equipment for kaolin processing. It has the following advantages: 1. good dust collection. The equipment adopts ...

consulter en ligne

CALCIUM CARBONATE (GCC) - Hosokawa Alpine

2020.6.23 ANR-CL + Cell Mill Specific energy consumption (kWh / t) Product fineness d 97 (µm) 100 50 20 10 5 2 SO-SF ATR ANR with Cell Mill SO AWM AWM-F SO-SF = Ball Mill Super Orion SUPER FINE SO = Ball Mill Super Orion ATR = Agitated Ball Mill AWM = Table Roller Mill AWM-F = Latest-generation table roller mill ANR =Vertical Agitated Mill

consulter en ligne

Structural and thermal behavior of proclay kaolinite using

2015.2.1 The authors [31] have used planetary ball mill to process natural kaolin where the major mineral constituent is a high-defect kaolinite (95 wt%) combined with a low quartz content. Milling times of 1 h to 6 h are selected with 30 cm 3 of concentrated formamide solution.

consulter en ligne

About Us Prominer (Shanghai) Mining

About Prominer: Prominer has been devoted to mineral processing industry for decades and specializes in mineral upgrading and deep processing. With expertise in the fields of mineral project development, mining, test study,

consulter en ligne

What is the difference between vertical mill and ball mill?

2022.1.12 Ultrafine vertical mills and ball mills are common large-scale industrial grinding equipment and are widely used. However, many people still do not know how to choose the most suitable equipment when purchasing equipment. Let’s take a look at the difference between ultrafine vertical mill and ball mill.

consulter en ligne

fr/moulin à boulets vertical kaolin.md at main hongyib/fr

Contribute to hongyib/fr development by creating an account on GitHub.

consulter en ligne

Kaolin vertical roller mill_PRODUCT_Tongli Machinery

A kaolin vertical roller mill is a specialized equipment used for grinding and processing kaolin into kaolin powder.Kaolin is a non-metallic mineral. It is a kind of clay and clay rock mainly composed ... Ball mill grinding media. Vertical roller mill grinding roller wheel hub. Rotary kiln shell. Vertical roller mill grinding roller tyre.

consulter en ligne

The advantages and disadvantages of ball mills

2020.9.21 1.The output of ball mill is much larger than that of mineral mill. Although it is smaller than fine crusher, it is a moderate product. A production line group requires suitable machines. The current production efficiency ball mill is fully capable, and the fast work of the fine crusher causes other supporting machines to fail to keep up. So ...

consulter en ligne

Types of mills for high-energy milling: A-ball mill, B-planetary mill ...

Samples with 10 µm particle size were activated in The Fritsch Pulverisette 5 Ball Mill (Two Chamber Mill) at 400 rpm at different solid/ball ratios (1/10, 1/20, 1/30) and at different times (0 ...

consulter en ligne

Comparing Ball Mills And Vertical Roller Mills for Fly Ash

2020.4.20 Kaolin Powder Making Machine: Raymond Mill and HLMX Superfine Vertical Mill Aug 6, 2021 Preparation Method of Superfine Powder, Grinding mill Plant 325-2500 Mesh

consulter en ligne

Roller Mill - Springer

2023.7.4 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table). The roller mill with several grinding rollers as working components rolls along the grinding ring or the grinding table to crush the ...

consulter en ligne

Cement Grinder Mill Price, 2024 Cement Grinder Mill Price

China Grinder Machine Ball Mill Energy Saving Ball Grinding Mill Machine Price Industry Cement Coal Ceramic Ball ... Coal Mill Vertical Grinding for Cement Manufacturer Price Vertical Type Cement Mill. US$ 50000-80000 ... Bauxite, Kaolin, Iron Ore , Cer. 1 / 3. Favorites. Good Price Cement Grinding Mill for Portland Cement Factory Machinery ...

consulter en ligne

Ball Mill Manufacturer - Henan Zhengzhou Mining

2021.7.16 Ball mill is mainly used for grinding in mining (metallic minerals and non-metallic minerals), cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, ect.It follows more crushing and less grinding principle to save energy. The feed size to ball mill shall be smaller than 25mm, the output size can

consulter en ligne

- concasseurs de diamants noirs

- plantas chancadoras de piedras

- afrique mouture du sorgho de la plante du sud

- machine de production de cacao de lallemand

- portable concasseur mobile cone

- caracteristiques convoyeur a bande

- feu équipement de test à partir de chine

- fabricants de concasseurs à mâchoires dans concasseur mobile

- piste cobra 1100 machoire de concasseur specifiions

- état de l art concasseur de pierre

- prevoit matrice de pastilles fournisseurs de moulins

- la machine va pulveriser le verre dans le sable

- le criblage le calibrage

- broyeur à galets cimenterie

- mauritanie mines de minerai de fer a la vente