How Does a Stone Crusher Work - Tyne Tees Crushing Screening

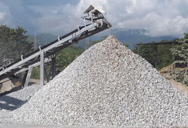

2020.11.26 Simply put, a stone crusher is a large piece of mechanical, industry machinery that reduces large materials such as rocks, minerals, and stones into more

consulter en ligne

Stone Crushers: A Technical Review on Significant Part of

2022.5.13 Crushers are one of the essential quarrying machines used in foresaid industries which are generally used to reduce the size of large size rocks into small

consulter en ligne

How Does a Stone Crusher Work Mechanically? - SMMVIK

2023.11.28 How Does a Stone Crusher Work Mechanically? Welcome to the world of stone crushers, where rocks are transformed into valuable construction materials! These

consulter en ligne

How does a stone crusher work mechanically? - LinkedIn

2023.2.16 A stone crusher works mechanically by using compression to reduce the size of rocks and stones into smaller sizes. The stones are placed into the crusher which

consulter en ligne

How To Operate A Stone Crushing Plant Safely

2023.12.25 To know how to operate the stone crushing plant correctly and safely, first of all, you have to complete the installation of the stone crushing plant

consulter en ligne

(PDF) Design of Impact stone crusher machine

2019.5.31 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of ...

consulter en ligne

Cone crusher basics in 4 minutes - rockprocessing.sandvik

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive.

consulter en ligne

How does a stone crusher work? - LinkedIn

2022.12.20 A stone crusher works by using a combination of compression and impact force to reduce the size of rocks or stones. The material is fed into the crusher, where it is compressed between a pair of ...

consulter en ligne

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Table 1 Summary of experimental and analytical work carried out on stone crushers (2011–2021) Full size table. 1.2 Effect of Various Parameters on Crusher Performance and Efficiency. ... Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortment of enormous stones. It normally highlights a huge

consulter en ligne

How it Works: Crushers, Grinding Mills and

2017.6.2 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment can

consulter en ligne

What Are Jaw Crushers and How Do They Work? Oreflow

2019.3.28 The single-toggle jaw crusher has less shafts and bearings compared to double-toggle jaw crushers. Only one toggle goes from the bottom of the swinging jaw back to the fixed point. Double-toggle jaw crushers. In a double-toggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and

consulter en ligne

4 Types of Stone Crushers' Maintenance and Efficient

2023.2.15 Horizontal Shaft Impact crusher (HSI) Impact crusher working animation The working principle of impact crusher is that the spinning rotor under the driving of the motor can genetate strong impact force which make blow bars crush stone material into small pieces. Then the crushed material would be thrown by hammers towards, which

consulter en ligne

CPCB’s new guidelines for India’s stone crusher sector a

2023.5.26 A minimum area should be mandated by SPCB for establishment of a crusher, which can accommodate crusher green area, storage area and vehicular parking section. SPCB should work with stone crusher associations for the construction of metalled road throughout the crusher zones; Point 1: accepted and included. Provision of timing

consulter en ligne

How Does A Cone Crusher Work: Understanding The

2023.7.31 The cone crusher has a high reduction ratio, ensuring efficient material crushing. Discharge: This is the final stage of the crushing process. When the material is crushed into the preferred size, it exits the cone crusher through an opening at the bottom. The entrance is located between the mantle and the bowl liner.

consulter en ligne

How to Make Crusher in Palworld, Watering Required

2024.1.20 Once the construction is complete, and you try to use the Crusher, you can get the following message “Required: Watering”. What this means is that you need to get a Pal that has the Watering Skill. This includes Water type Pals, such as: Fuack, Pengullet, Penking, Teafant, Celaray, Gobfin, Surfent, Kelpsea, Azurobe, Relaxaurus, and Jormuntide.

consulter en ligne

A Comprehensive Guide to Stone Crusher Machines - AGICO

2023.2.22 Jaw crusher: The jaw crusher is the main component of a stone crusher machine. It works by using pressure to crush the rocks and stones into smaller, usable pieces. Conveyor belts: The conveyor belts are used to transport the crushed stones to the next stage of the process. They are designed to be durable and able to handle the weight

consulter en ligne

What Kind Of Hammer Mill Stone Crusher Do You

2023.4.12 Factors influencing the choice of a crusher also include the required output size. If you need a fine powder, a hammer mill with a high speed rotor may be ideal. But if you need a coarser output, a lower rotor

consulter en ligne

how to stone crusher machine works - LinkedIn

Published Mar 10, 2023. + Follow. Stone crusher machines are designed to crush and grind various types of rocks and minerals into smaller pieces. The process of crushing and grinding starts with ...

consulter en ligne

Stone Crusher Plant Setup - Machinery Partner

The stone crusher plant consists of a crushing setup of excavators, feeders, primary and secondary crushers and screeners. They all work together to crush stone as efficiently as possible. Conveyors connect everything, moving the crushed material from one station to the next. Stone crusher plant equipment is divided into two categories:

consulter en ligne

7 Types of Stone Crusher and How to Choose the Best?

2021.9.23 4. Sand Making Machine. The work of the impact sand making machine is continuous. It uses high-speed moving materials to strike iron, strike each other and friction between the materials to break. There are two crushing methods: "stone-on-rock" and "stone-on-iron".

consulter en ligne

Should know all about Stone Crusher Plant - Machine Thug

Stone Crusher plant Capacity. The stone crusher plant will available from 50 TPH to 600 TPH (ton per hour). The plant can produce the 8 variants of material. Just to get the different variant material you also need to put the screening plant that just separates the different materials according to client or market demand. Stone Crusher plant works

consulter en ligne

Jaw Crusher SpringerLink

2023.6.21 Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable. The movable jaw plate approaches the fixed jaw plate periodically to realize the functions of crushing, splitting, breaking, and impacting, thus to coarsely or mediumly crush materials with various hardness. It was invented by

consulter en ligne

7 Types of Stone Crusher and How to Choose the Best?

2021.9.23 7. Roller Crusher. The work of the roller crusher is continuous. The stone is located between two parallel cylindrical rollers that move toward each other. The friction force between the stone and the roller bites the stone into

consulter en ligne

Understanding the Cone Crusher Working Principle: How It

2023.2.23 The cone crusher’s unique design allows it to rotate at high speeds and crushes material through a combination of compression and impact. When the cone crusher is in operation, the spindle rotates around its own axis, causing the mantle to move back and forth. The mantle is the cone-shaped part of the crusher that moves in a circular motion ...

consulter en ligne

How Does Different Stone Crushers Work?

2021.6.23 How Does Different Stone Crushers Work? In the process of mineral processing, the operation of reducing the particle size to 20-5mm is called crushing, and the corresponding equipment is crusher. Commonly used crushing equipment are: jaw crusher, cone crusher, impact crusher, roller crusher, hammer crusher, etc. 1. Jaw Crusher.

consulter en ligne

How does a Rock Crusher Work - Jaw Crusher - 911

2021.11.22 A jaw crusher frames are of sectionalized construction to facilitate handling. This design minimizes heavy lifts makes the crusher suitable for installations where parts must be passed down a shaft or through a tunnel. End members are attached between side members with vertical tongue and groove joints and held together with

consulter en ligne

How does a stone crusher work mechanically? - LinkedIn

2023.2.16 Mechanically, a stone crusher works by using a high pressure to break down the stone material into smaller pieces. The machine is composed of a crusher, a vibrating screen, a belt conveyor and a ...

consulter en ligne

The Complete Guide to Primary Crushing,

2023.2.28 Primary crushing is commonly used in the aggregates industry for producing crushed stone and gravel. It is also used in the mining industry for processing ores and minerals. ... The working principle of

consulter en ligne

Jaw Crusher Explained - saVRee

Size Reduction) A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral(s) from the waste (gangue) material.Waste material can be discarded or recycled allowing

consulter en ligne

Design of a crushing system that improves the crushing

2016.2.10 will result in the jaw crusher producing stones above 30mm diameter which will strain the cone crusher and will result in it breaking down. Decreasing the space between jaws will result in the process being extremely slow. Therefore a system that is faster and produces smaller diameter stones of less than 12mm diameter is required. 3.

consulter en ligne

Cone crusher basics in 4 minutes - rockprocessing.sandvik

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing ...

consulter en ligne

How does a stone crusher work? - LinkedIn

Published Dec 23, 2022. + Follow. A stone crusher works by using compressive force to break down rocks and other materials into smaller pieces. The crusher is powered by a diesel engine, and the ...

consulter en ligne

Primary Crusher - an overview ScienceDirect Topics

Handbook of Conveying and Handling of Particulate Solids. G. Lodewijks, ... A. Newman, in Handbook of Powder Technology, 2001 2.1 The primary crusher. The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour). The driving flywheel has a diameter of 2.5 meters and is

consulter en ligne

- Algérie de poudre de pierre de quartzite en Nouvelle Caldonia

- Mini Mill Grizzly G8689

- poids de kg de pierre concassée par pied cube

- pièce de rechange cale dragon concasseur

- concasseur de pierre machines d occasion

- surface de meulage concasseur de ciment

- processus de preparation de charbon installation de traitement

- manteaux de concasseurs giratoires

- automatique fabricant de pierre usine de concassage

- pollution lors de l'extraction de charbon

- prix des équipements de concassage de pierre en Nouvelle Caldonia

- à moudre en marbre

- la machoire du commerce équitable concasseur

- concassage de pierre en pierre

- broyeurs verticaux à pression de meulage