Ball Mills Agitated Media Mills - Hosokawa Alpine

Overview of our ball mills and agitated media mills. The classic ball mill Super Orion S.O. is suitable for dry hard crushing and achieves finenesses of under 10 µm. For superfine dry

consulter en ligne

Estimating Residence Time Distributions in

2022.12.8 This paper compares two deconvolution methodologies used to estimate residence time distributions (RTD) in industrial closed-circuit ball mills. Parametric and non-parametric deconvolution

consulter en ligne

(PDF) Grinding in Ball Mills: Modeling and Process

2012.6.1 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding

consulter en ligne

Ball milling: a green technology for the

Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials.18 Being an environmentally-friendly, cost

consulter en ligne

Ball Mill - RETSCH - powerful grinding and homogenization

RETSCH offers the largest selection of laboratory ball mills in the market! Ball mills are among the most variable and effective tools when it comes to size reduction of hard,

consulter en ligne

Christian Pfeiffer Ball Mill BAM for Industrial Minerals

The BAM ball mill for industrial minerals is designed to be particularly efficient thanks to our process know-how. This is because the efficiency of a mill depends on its internals. All

consulter en ligne

Modelling the performance of industrial ball mills using

1987.7.1 Ball milling is an energy-intensive unit operation and usually consumes a major proportion of the power drawn by a typical mineral processing plant. Hence,

consulter en ligne

A direct approach of modeling batch grinding in ball mills

2002.4.1 The grinding operation in a ball mill is a capital- and energy-intensive process. Hence, a marginal improvement in the efficiency of mill operation will be of

consulter en ligne

Full article: Real-time slurry characteristic analysis during ball ...

2022.5.23 The vibration data in the (3–4) kHz range showed a strong negative correlation with the slurry viscosity at a shear rate of 24s −1. Our results confirm that the

consulter en ligne

球磨机_百度百科

2023.8.15 球磨机是物料被破碎之后,再进行粉碎的关键设备。这种类型磨矿机是在其筒体内装入一定数量的钢球作为研磨介质。它广泛应用于水泥,硅酸盐制品,新型建筑材料、耐火材料、化肥、黑与有色金属选矿

consulter en ligne

A direct approach of modeling batch grinding in ball mills

2002.4.1 The grinding operation in a ball mill is a capital- and energy-intensive process. Hence, a marginal improvement in the efficiency of mill operation will be of immense economic benefit to the industry. A typical scale-up procedure for designing large industrial-scale mills consists of several steps (Herbst and Fuerstenau, 1980).

consulter en ligne

Effects of Mill Speed and Air Classifier Speed on

2020.5.12 Cement ball mill reject sample from a industry located in Pakistan in Pezu District KPK. Study about cement was done for . Ordinary Portland cement with 5% gypsum content and 95% clinker. During the sampling time, the capacity of cement mill was 120 t/h and the specific energy utilization was 30 kWh /t and the Mill balls

consulter en ligne

球磨是什么?实验室球磨工艺介绍 - 知乎

2022.9.27 球磨,英文ball-milling,是一种主要以球为介质,利用撞击、挤压、摩擦方式来实现物料粉碎的一种研磨方式。 在球磨的过程中,被赋予动能的研磨球会在密封的容器内进行高速运动,进而对物料进行碰撞,物料在受到撞击后,会破碎分裂为更小的物料,从而实现样品的精细研磨。

consulter en ligne

Ball milling: a green technology for the preparation and ...

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the prep-

consulter en ligne

Glass Milling in the Production of Specialty Glass Powders

2021.9.2 Industrial ball mills can coarsely crush relatively large material, while lab-grade ball mills are suitable for finely milling glass to the micron level and further. ‘High energy’ ball milling offers users the capacity to reliably grind the material into nanoscale particles. 4. Centrifugal Mill. The majority of centrifugal mills are found ...

consulter en ligne

Advanced comminution modelling: Part 2 - Mills

2020.12.1 An industrial ball mill was then laser scanned and surveyed, including measurements of residence time distribution. Simulations using the discrete element method were then conducted and the model was applied to simulate closed-circuit operation, resulting in good agreement between measured and predicted size distributions and

consulter en ligne

Table 1 . Specifications of industrial ball mills (PBM SBM)

Join for free. Download Table Specifications of industrial ball mills (PBM SBM) from publication: Investigation of laboratory conditions effect on prediction accuracy of size distribution of ...

consulter en ligne

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012.6.1 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made ...

consulter en ligne

Ball mill, Ball grinding mill - All industrial manufacturers

ball grinding mill Ф2200×5500. horizontal for ore for cement. Final grain size: 74 µm - 400 µm. Rotational speed: 21 rpm. Output: 10 t/h - 20 t/h. Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed.

consulter en ligne

Ball Mill: Operating principles, components, Uses,

2022.11.30 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis.

consulter en ligne

A Review of the Grinding Media in Ball Mills for Mineral

2023.10.27 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the

consulter en ligne

Industrial Technologies Program - Energy

2012.11.14 Besides mill optimization, the impact 20% due to its ability to optimize spectra obtained could be used in three ball to rock ratio. additional ways. First, the signature data The grinding efficiency of semi - • Improves equipment life and from industrial SAG mills can set the autogenous and ball milling depends on reduces operation costs.

consulter en ligne

Ball Mill - Sand Ball Mill Manufacturer from Mumbai

Raymer Engineering is one of the leading manufacturers, supplier and exporter of Ball Mills in Mumbai, India.Our Ball Mills complies with international standards. In this product range, we also offer shrouded ball mills that are extensively used in various industrial sectors for dispersion of enamels primers, powder distempers and cement ...

consulter en ligne

Optimization of Solids Concentration in Iron Ore Ball Milling

2019.6.18 Important advances have been made in the last 60 years or so in the modeling of ball mills using mathematical formulas and models. One approach that has gained popularity is the population balance model, in particular, when coupled to the specific breakage rate function. The paper demonstrates the application of this methodology to

consulter en ligne

Ball Mills Agitated Media Mills - Hosokawa Alpine

Applications of ball mills and agitated media mills Ball mills have been used to produce high-quality mineral flours for many years. They are suitable for grinding medium-hard to extremely hard, brittle and fibrous materials.Specific applications include industrial minerals, metal oxides, glass, graphite, limestone, quartz, zircon sand, talc, ceramic paints,

consulter en ligne

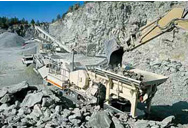

How it Works: Crushers, Grinding Mills and Pulverizers

2017.6.2 The feed enters one end of the ball mill, and discharges out the other end. Ball mills vary greatly in size, from large industrial ball mills measuring more than 25 ft. in diameter to small mills used for sample preparation in laboratories. Rod mills are similar to ball mills and use metal rods as the grinding media. Pebble mills use rock ...

consulter en ligne

Machines Free Full-Text Planetary Mill with Friction

2019.5.21 Processing in planetary ball mills is well suited to a large number of applications because they are easy to operate and versatile, grinding faster than other mills. Research related to planetary mills are mainly about the process evaluation, and there are few studies on the mechanical design of such equipment. This paper describes the

consulter en ligne

Relationship between breakage parameters and process variables in ball ...

1987.7.1 The performance of the No. 2 secondary ball mill, 3.2 m diameter and 3.05 m long, was studied in this investigation. The rod mill and ball mill discharges are pumped through a variable speed pump to a cluster of 0.5 m diameter cyclones. The cyclone underflow gravitates to the ball mill while the cyclone overflow is the grinding circuit product.

consulter en ligne

Modelling the performance of industrial ball mills using

1987.7.1 Ball milling is an energy-intensive unit operation and usually consumes a major proportion of the power drawn by a typical mineral processing plant. Hence, substantial economic benefits can be achieved by optimal design and by operating ball milling circuits under optimum process conditions. This requires an accurate ball mill

consulter en ligne

Grinding Media - Union Process

Alumina Balls and Satellites. Union Process is the one source for 90%, 94%, 99.5% and 99.9% alumina media. 90% alumina is available in satellites and rod/cylinders. 94% alumina balls have excellent wear resistance with

consulter en ligne

Ball Mill Jar at Thomas Scientific

Polished stainless steel (grade 304) grinding jars for planetary ball mills. Each jar set includes grinding jar, lid, silicon sealing gasket and a mixed sizes of stainless steel grinding balls. Grade 304 is the most widely used austenite steel, also known as 18/8 for its composition of 18%. Related Products: Ball Mill.

consulter en ligne

Process engineering with planetary ball mills - RSC Publishing

Planetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of planetary ball mills has extended to mechanochemical approaches. Processes inside planetary ball mills are complex and strongly depend on the processed material and synthesis and, thus, the

consulter en ligne

(PDF) Investigation of the effect of industrial ball mill liner

2021.6.21 First, an industrial scale ball mill with a Smooth liner type is simulated. Then, by changing liner type, i.e. Wave, Rib, Ship-lap, Lorain, Osborn, and Step liners, six other independent ...

consulter en ligne

SAG Mill Testing - Test Procedures to Characterize Ore

2022.6.29 Primary Ball Mill Sign. Plot Grey : Industrial/Production Blue : Testing Size K 80 (mm) 0.001 0.01 0.1 1 10 100 1,000. Although HPGR is a more recent innovation in hard rock mining, it has gradually been accepted by the industry. There are now small-scale methodologies available to develop

consulter en ligne

Tumbling Mills Encyclopedia MDPI

2021.1.19 Tumbling mills have been widely implemented in many industrial sectors for the grinding of bulk materials. They have been used for decades in the production of fines and in the final stages of ore comminution, where optimal levels for the enrichment particlesrsquo; sizes are obtained. Even though these ubiquitous machines of relatively

consulter en ligne

ball mill - thyssenkrupp Polysius

Ball Mill. The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding. Used in combination with the sepol ...

consulter en ligne

Mechanistic modeling and simulation of grinding iron

2021.11.1 The work demonstrates the calibration of industrial-scale ball mill model parameters from laboratory milling tests on Platinum Group Metals (PGM) and Itabirite iron ores. Minor fine-tunning of a single model parameter was required to simulate the large-diameter industrial mills, demonstrating the validity of the approach for ores as distinct as ...

consulter en ligne

Energies Free Full-Text Increasing Energy Efficiency and

2020.12.21 Tumbling mills have been widely implemented in many industrial sectors for the grinding of bulk materials. They have been used for decades in the production of fines and in the final stages of ore comminution, where optimal levels for the enrichment particles’ sizes are obtained. Even though these ubiquitous machines of relatively simple

consulter en ligne

- Machines De Meulage Pour Raymond

- systèmes d assistance pour les broyeurs à marteaux

- broyeur à glaons professionnel

- petite echelle mobiles des concasseurs de sable mobiles

- machoire de pierre plaques taille

- prix des machines de briques creuses en coimbatore

- mines dor et usines de traitement de lorge

- fabricant de charbon de transport a mumbai

- broyeurs Indonésie boulets en philippines

- fournisseurs de machines de meulage concrètes Indonésie Nagpur

- solide convoyeur à bande nn de type

- toyota mitrailleuses de calibre

- simmons concasseur à cone 2

- prix des minerais de limonite de fer

- projet broyage broyeur