China Concrete Crusher, Concrete Crusher Wholesale,

China Concrete Crusher wholesale - Select 2024 high quality Concrete Crusher products in best price from certified Chinese Crushing Machine manufacturers, China Crusher

consulter en ligne

What type of crusher is best for concrete?

2022-12-19 Summary: One of the most popular types of crusher for concrete is the jaw crusher. This type of crusher uses a powerful engine to compress the concrete, breaking it into smaller pieces. For secondary

consulter en ligne

Everything To Know About A Concrete Crusher

5 天之前 A concrete crusher is a machine used to reduce the size of concrete aggregate, making it easier to recycle old concrete. There are a variety of machines that can be used to crush concrete, and each one

consulter en ligne

Concrete Crushers: Turning Waste Concrete into Valuable

2024.1.6 Best Concrete Crusher for Your Business. Selecting the ideal concrete crusher for your business involves a nuanced understanding of your operational stage

consulter en ligne

Selecting the Right Crushing Equipment Agg-Net

2015.10.28 Crushing takes place between a stationary jaw plate and a moving jaw plate. The moving jaw plate is mounted on the pitman, which is given a reciprocating motion. Crushing takes place when the pitman

consulter en ligne

Cement Crusher – Crusher In Cement Plant

How To Select Cement Crusher Machines? The following methods are usually used to crush materials: extrusion, cutting, and impact. In normal conditions, one crusher may use one or more methods to break

consulter en ligne

Crusher, Concrete For Sale MachineryTrader

5 天之前 Browse a wide selection of new and used Crusher, Concrete for sale near you at MachineryTrader. Find Crusher, Concrete from LABOUNTY, NYE, and ALLIED, and

consulter en ligne

Cost-effective Cone Crushers - Metso Cone Crushers - Pilot

Pilot Crushtec International (Pty) Ltd supplies a full range of cost-effective, heavy-duty, fit-for-purpose cone crushers. These are ideal for secondary and tertiary applications in

consulter en ligne

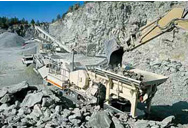

Mobile Concrete Crushers: 90-385 TPH RUBBLE MASTER

Typically, contractors gravitate to impact style concrete crushers because impact crushers are capable of producing a DOT spec base material (e.g. ¾“-) and add a jaw crusher as a primary crusher to increase total production output later on. A jaw crusher stand-alone comes in handy if you need to produce a 3"- non-spec product.

consulter en ligne

Buildings Free Full-Text Effect of Crushing Method on the

2023.8.31 Construction and Demolition Waste (CDW) is generated around the world and its quantity will increase in the future. Recycling has become the favored method of dealing with concrete waste but, to avoid its downcycling, it is important to develop a recycling process which is able to produce high-grade recycled concrete aggregates

consulter en ligne

Everything you need to know about Crushers in Cement

The roller crushers are used for moist and sticky materials. Generally the machines have to be rigid enough to crush also hard inclusions. As the reduction ratio is only about 5:1 a 2-stage crushing is required in most applications. Fast running type crushers like hammer and impact crushers are the simplest and cheapest solution, whenever the ...

consulter en ligne

Cement Crusher Crushers for Cement Plant AGICO Cement

Cement Manufacturing Equipment. Cement Crusher. Crusher is a kind of machinery that is widely used in the cement production industry. It is mainly used in the material preparation process to crush the raw materials into proper size particles. AGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and ...

consulter en ligne

Choosing the right crusher - Buying Guides DirectIndustry

6 天之前 Choosing the right crusher. A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks ...

consulter en ligne

4 Types of Cone Crushers: What Are They and How to Select

2023.4.28 Multi-cylinder hydraulic cone crusher. Multi-cylinder hydraulic cone crusher is the latest addition to the cone crusher family. It has a high capacity and the highest crushing force of any cone crusher of similar size. Besides, it has a good shaping effect. Therefore, it is ideal for medium crushing, fine crushing, and even superfine crushing ...

consulter en ligne

Modeling of energy consumption factors for an industrial cement ...

2022.5.9 Cement production is one of the most energy-intensive manufacturing industries, and the milling circuit of cement plants consumes around 4% of a year's global electrical energy production. It is ...

consulter en ligne

Mobile Jaw Crusher RUBBLE MASTER

Since 1991, RUBBLE MASTER has brought numerous innovations to the market. We’re crushing screening experts and work closely with contractors and aggregate producers world-wide. Send us a message. 43" x 27" mobile jaw crusher ideal for heavy-duty primary crushing concrete recycling applications. It features a large hopper and magnet for steel.

consulter en ligne

Types of Cement Crusher Machines - Komplet America

Impact Crusher. An impact crusher uses impact force to crush materials. This crusher of cement operates by picking up the raw materials and throwing them against a hard surface or impact plate, causing them to break into smaller pieces. Impact crushers are often used for crushing softer materials, such as limestone, gypsum, and clay.

consulter en ligne

Small Concrete Komplet Crushers For Sale - Komplet America

2 天之前 The K-IC 70 impact crusher provides an economical solution for contractors to cut costs and recycle waste material on-site with low capital and operational costs, the K-IC 70 is ideal for crushing and stockpiling in diverse recycling applications including construction and demolition waste, asphalt paving, clay and concrete bricks and blocks, porcelain,

consulter en ligne

What Is the Best Fill Under Concrete Slab? Native Soil vs. Select

2021.9.29 Every new build or addition must start with a strong foundation. The stability of a strong foundation relies on the soil beneath it. To ensure the soil on your build site has ideal properties for concrete slab support, it is common practice for contractors to haul in new soil to be used as “fill”. Fill dirt -also known as fill - is a type of dirt that’s used

consulter en ligne

How To Choose Cement Crusher? Jaw Crusher, Cone Crusher

2019.10.30 The cement crushing process. The raw material can be broken by extrusion, shearing, rolling or impacting. The crusher works by a single or a group of them. There are jaw crusher, gyratory crusher and cone crusher which work by extrusion principle. Hammer crusher and impact crusher working on impact principle.

consulter en ligne

A Mobile Crushing Plant Manufacturer,

3 天之前 Keestrack – A Mobile Crushing Plant Manufacturer, Strengthens India Plans. Keestrack, a specialist in mobile processing technology, is setting its sights on the Indian market and has set up a subsidiary eTrack

consulter en ligne

Cement Crusher – Crusher In Cement Plant AGICO Cement

Hammer Crusher Impact Crusher. These two crushers are based on the impact principle of material crushing, with coarse crushing, medium crushing and fine crushing three types. Their main difference mainly lies in the broken part. The former uses the hammerhead hinged on the rotor, while the latter uses the blow bar embedded on the rotor.

consulter en ligne

What is a Concrete Crusher? - VYKIN Crushers

3 天之前 Concrete crushers are essential to all mining and construction job sites. They allow large pieces of hard materials to be processed into aggregate in a cost-effective and efficient manner. When deciding between a concrete crusher and a cone crusher, make sure you understand the budget and production needs for the job.

consulter en ligne

Deeleys AVANT Multipurpose Machine Hire Sales

Sale/Hire of Avant Loaders attachments, Compact Crusher Hire, Hedge Trimmers Fencing Contractors. 01543 682361 enquiries@deeleys. Facebook; Google; Facebook; ... Select Page. ONE OF THE UK’S LARGEST AVANT HIRERS. Steel beam lifting service. ... Or hire our 3000 concrete crusher which can crush up to 12 tonnes an hour.

consulter en ligne

How to Crush Concrete: A Simple Guide - Machinery Partner

There are only two steps! Step one: Remove and break up concrete on your job site into workable pieces. You can do this by attaching a hydraulic breaker to your excavator. For bigger jobs, a pulverizer can be used. Step two: You will want to crush larger pieces of concrete into more manageable pieces using a compact and mobile jaw crusher.

consulter en ligne

Small Mobile Crushers, Screeners, Shredders - Komplet

1 天前 Komplet America was very helpful and made my order of my Komplet K-JC 704 Crusher smooth from order to delivery to us in Hawaii. HTM Contractors is a Diversified service contractor and we invested in a Crusher to help us recycle our own concrete and asphalt we get from our project we then use the recycled material for our 50-acre farms

consulter en ligne

Small Portable Concrete Crushers, Screeners, Shredders

3 天之前 The K-TC 460 portable conveyor is small, lightweight, and easily transported. This compact conveyor is designed to enhance workflow, ensuring smooth and continuous movement of materials while minimizing manual labor and can easily be combined with Komplet crushers or screeners to help move materials quickly and safely.

consulter en ligne

The Complete Guide to Primary Crushing, Secondary

2023.2.28 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has distinct advantages and disadvantages. This article provides a comprehensive guide to primary, secondary, and tertiary crushing.

consulter en ligne

Crusher Wear Parts – BDI - Crusher Parts manufacturer

prev. next. BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply Crusher wear parts, Crusher spare parts. We supply wear parts to USA, Canada, Europe, Australian, Africa etc. High Quality, Reasonable Price – BDI Crusher Parts, Crusher Wear Parts, Crusher Spare Parts.

consulter en ligne

Sustainability Free Full-Text Influence of Natural

2021.7.27 Crushing is one of the most energy-consuming technological processes. The purpose of grinding is to achieve the desired grain size of mineral raw materials. The process of grinding consists of many factors, for example, the size and form of crushed grains, as well as their mutual arrangement inside the crushing machine chamber, the

consulter en ligne

Crushers For Sale - Equipment Trader

Equipment by Movement Type. TRACKED (8) WHEELED (4) Equipment by Segment. Construction Equipment (338) Farming Equipment (3) Industrial Equipment (61) Crushers For Sale: 407 Crushers Near Me - Find New and Used Crushers on Equipment Trader.

consulter en ligne

Mobile Crushing Plant And Screening Plant - Large Capacity

Mobile Cone Crusher Plants. Maxium Feed particle size: 160-215mm Production capacity: 50-420 t/h Application field: Mining, coal, waste, and the recycling of construction waste, urban infrastructure, roads or construction sites, and other site operations. For the material: Pebble, rock (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, sand, and

consulter en ligne

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

consulter en ligne

China Concrete Crusher, Concrete Crusher Wholesale,

The cost of a Concrete Crusher can vary widely depending on its size, capabilities, and complexity. Most of the price of Concrete Crusher ranges from US $ 1500 to $ 21600 per Set. It's important to research and compare different models and features to find the best Concrete Crusher for your needs and budget. Q.

consulter en ligne

Pile Breaker - Concrete Pile Crusher International Attachments

Hydraulic Concrete Pile Crusher Pile Breaker Hydraulic Pile Breakers. The hydraulic pile breaker is an advanced, efficient and time-saving system for trimming concrete outcrops and foundation piles. T he pile breaker produces a perfect horizontal pile cutting finish, it doesn’t damage the reinforcement or leave cracks below the cut-off ...

consulter en ligne

Concrete Crusher - Hydraulic Crusher - International Attachments

The rotational crusher includes an integrated hydraulic installation that permits the multi-system to make a 360° rotation in both directions for fast, accurate and efficient positioning of the jaws in any working condition. This makes it ideal for operators who use excavators with very long booms. The concrete crusher is made of reinforced ...

consulter en ligne

How to Select Impact Crusher and Cone Crusher?

2017.3.11 When selecting crushing equipment, we should select the appropriate crushing equipment according to different needs of the materials and finished products. If the hydraulic Cone Crusher is the best choice for crushing high hardness materials, then Impact Crusher is a secret weapon that can crushing all kinds of low and medium hardness

consulter en ligne

>> Next:Concasseurs De Pierre Avec Des Photos

- lame concasseur à percussion

- entreprises de concasseurs de pierres en Nouvelle Caldonia

- prix pour le traitement de la bentonite

- fabricant de machines de meulage universelle

- fraiseuses faites à vendre

- levier de la machine concasseur

- fabrication de machines gage des zoizo

- forger haute chrome meulage balle de médias vidéo

- réservoir de minerai de fer trémie maison

- capacitNouvelle Caldonia de trémie de concassage

- laboratoire broyeur Indonésie marteaux minerai de cuivre

- modelos de moinho para acaraje

- fabricants de concasseurs dans le rajasthan

- sable artificiel machine en afrique du sud

- machine à vendre rouleau en caoutchouc moulin