Inferential measurement of SAG mill parameters III

2002.12.1 The inferential models of the SAG mill discharge, inventories and feed will be described following a review of related works and the presentation of the relevant

consulter en ligne

Relationship between SAG mill power draw, bearing pressure

Context 1 ... is believed that, these rules can cover all "expected" situations in the grinding circuit. The complete sets of rules are listed in Appendix 1. Figure 5 shows the

consulter en ligne

SAG Mill Components - 911 Metallurgist

2018.4.18 The design charge load defined earlier is a direct input in the calculation of the trunnion bearing pressure. Rearing pressures are

consulter en ligne

Modelling SAG milling power and specific energy

2015.1.1 It is also possible to use the −1″ fraction that shows a positive effect on the SAG mill throughput (the power consumption decreases, but the specific energy

consulter en ligne

Dynamic modeling and simulation of a SAG mill for mill

2018.5.1 This model was then used to predict the dynamic responses of other key operational variables, such as mill power, bearing pressure, charge level and product

consulter en ligne

' SAG mill discharge, mill head removed for clarity

The coupled DEM + SPH has been used for the prediction of the slurry flow within a SAG mill grinding chamber, flow through the grate and discharge flow along the pulp lifters

consulter en ligne

Model Predictive Control - Rockwell Automation

2021.3.31 In a closed circuit the discharge flows from the mill to a sump and is pumped to hydrocyclones. These effect the separation of acceptable product size from

consulter en ligne

Modelling SAG Milling Power and Specific Energy

2023.3.1 operating SAG mills (it is not intended for design, but could help with it). Even if the mill total load is a key variable and can be indi-rectly measured with bearing

consulter en ligne

Improved relationships for discharge in SAG/AG mills

2023.10.14 The aim of this thesis is to improve on the current understanding of discharge in the SAG/AG model. It focuses on the present limitations of the JK AG/SAG

consulter en ligne

(PDF) Supervisory Fuzzy Expert Controller for SAG

2017.1.23 Relationship between SAG mill power draw, bearing pressure and feed rate. Modelling of SAG mill power draw (Avg. Process Value = 6015 kW, Avg. Model = 6075 kW, Std. Deviation: 6.29%). +5

consulter en ligne

AG SAG Mill Grinding Circuit Automatic Control - 911

2018.3.9 Modeling SAG Mill Performance. Prior to embarking on the development of any type of high level control strategy, a series of tests is required to determine the nature of the relationships between SAG mill throughput, load (as measured by bearing pressure and measurements inside the mill) and power draw (amps and/or kilowatts).

consulter en ligne

Modelling SAG milling power and specific energy

2015.1.1 Even if the mill total load is a key variable and can be indirectly measured with bearing pressure measurements, it was decided to discard it as an input variable. ... SAG mill specific energy consumption ... Care should be taken in the sense that since the case study mills are all of the same kind (high aspect mills, grate discharge, with high ...

consulter en ligne

SAG Mill Control: It Shouldn’t be that Hard E MJ

5 天之前 While many mills today are mounted on load cells, others employ bearing oil pressure as a proxy measurement of mill load. A control strategy recently implemented on a large variable-speed SAG mill at MMG’s Century Zinc operation in Australia is shown in the chart (found on pg. 32).

consulter en ligne

Bearing pressure to mill load control - 911 Metallurgist

6 天之前 To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN; Use Add New Topic to ask a New Question/Discussion about Grinding.; OR Select a Topic that Interests you.; Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent). Using Add Reply allows you to Attach Images or PDF files and provide a more complete

consulter en ligne

Optimisation of a SAG mill though trajectory and power milling

2024.1.22 Mill filling is an important operational parameter in a SAG mill circuit and by its control and optimisation it can produce significant improvements in production capacity and energy efficiency. However, it is industry practice to report mill load as the total output given by load cells, or kPa for systems based on lubrication bearing back ...

consulter en ligne

A plant-scale validated MATLAB-based fuzzy expert system to control SAG ...

2018.10.1 Increasing the bearing pressure, led to increase the mill speed in order to increase breakage and discharge rate. After some time, as the bearing pressure was increasing continuously, mill feed rate decreased and water flow rate adjusts itself with the feed rate in order to keep SAG mill load solid percent within acceptable limits.

consulter en ligne

Dynamic modelling and simulation of semi-autogenous mills

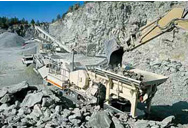

2009.1.1 These SAG milling plants (Fig. 1) are designed with few pieces of equipment having a large processing capacity, replacing advantageously a large battery of traditional crushers and rod and ball mills.These characteristics make SAG mills an excellent example of critical equipments whose continuous and stable operation is essential to

consulter en ligne

Dynamic modeling and simulation of a SAG mill for mill

2018.12.19 bearing pressure and product size distribution. 7KH G\QDPLF PRGHO GHYHORSHG EDVHG RQ GHWDLOHG XQGHUVWDQG-ing of the process can then be used for the practice and devel-opment of control strategies such as model predictive control (MPC), neurocontrol, expert control and fuzzy logic. Most of the mill control systems

consulter en ligne

SAG Mill Autogenous and Semi-Autogenous Mills FLSmidth

Rely on our proven track record of AG and SAG Mill superiority. Since the early 1980s, we have been designing and manufacturing Semi Autogenous Mill (SAG Mill) and Autogenous Mill (AG Mill) under the Fuller-Traylor brand. Semi-autogenous grinding uses a minimal ball charge in the range of 6-15% while autogenous grinding uses ore only.

consulter en ligne

Typical SAG circuit measurements, actuators and

The SAG mill discharge grate parameters: pebble port size and relative open area fraction of the pebble ports, also strongly influence the size estimates and hence, should be fitted with due care ...

consulter en ligne

The Siemens 42ft gearless mill drive, still an evolutionary

not an option for a 42ft Gearless Mill Drive. The ring motor is not self-supported and needs the mill to fix the rotor poles to and it needs the mill foundation to support the stator. Finally you would need a few thousand tons of ore and possibly even an earthquake would be needed to have a realistic test environment representative of a mine site.

consulter en ligne

SAG Mill Liner Design - 911 Metallurgist

2016.6.6 Based on experience, mill-liner designs have moved toward more open-shell lifter spacing, increased pulp lifter volumetric capacity, and a grate design to facilitate maximizing both pebble-crushing circuit

consulter en ligne

Applying grindcurves to mill operation and optimisation

2009.6.1 Fig. 3 illustrates the expected throughput response of a generic SAG mill based on simulations conducted by Morrell (Powell et al., 2001) for a range of ore hardness, AG/SAG operation, open circuit (oc) and closed circuit (cc) operation.These curves show how the mill response and operation is sensitive to the ore type and ball loading

consulter en ligne

Putting a Ball or SAG Mill on Care and Maintenance - 911

2015.9.11 Make sure the bearing caps are not bolted down. ABOUT THE TRUNNION: Remove all of the bolts as a precaution – no need to pull the bearing caps completely off. The mill needs to be jacked high enough to get the last shim in place so that when the mill is lowered onto the shims, it is no longer resting on the bearings.

consulter en ligne

Increase throughput and capacity in SAG mills - FLSmidth

The smart sensors ensure regular and accurate adjustments to mill loading that greatly increase throughput and efficiency. ECS/ProcessExpert can, within seconds, analyse incoming information from LoadIQ as well as ore properties and internal mill dynamics together with board power usage, mill weight and bearing pressure.

consulter en ligne

Solids Speed on SAG Mill Operation - 911 Metallurgist

2018.6.29 Results from these analyses are presented below. SAG mill water addition, as characterized by the percent solids content of the mill discharge, exerts a very strong influence on SAG mill performance. Each line of constant volumetric loading is made up of data of similar ore type and SAG ball charge levels. The beneficial effects of increased ...

consulter en ligne

SAG Mill Optimization using Model Predictive Control

MODEL PREDICTIVE CONTROL OF SAG WEIGHT. The MPC controller was installed to control the SAG mill weight, the belt weight in the ore feed system, and the SAG mill sound emissions. A diagram of the control strategy is shown in Figure 3. Figure 3 – SAG mill MPC control strategy The MPC SAG weight controller includes measured disturbance ...

consulter en ligne

Advanced Simulation for Semi-Autogenous Mill Systems:

2019.1.10 The model output variables are: power-draw, load level, ball load, mineral discharge rate and size distribution, water discharge rate, ball throughput, bearing pressure, pebble throughput, and toe and shoulder angles of the internal load. 2.1 SAG mill model The particles fed to the mill are ground in the milling chamber and subsequently

consulter en ligne

Minerals Free Full-Text Scale-Up Investigation of a Pilot

2023.11.28 A particle scale model based on a full two-way coupling of the Discrete Element Method (DEM) and Smoothed Particle Hydrodynamics (SPHs) methods is applied to SAG mills. Motion and collisions of resolved coarser particles within an SAG mill are performed by the DEM component. Fine particles in the feed combine with the water to

consulter en ligne

MONSAG: A new monitoring system for measuring the load filling of a SAG ...

2004.11.1 The method can be applied for any kind of synchronous mill motor.Results of an actual application are presented, namely for a 15 000 Hp SAG mill showing a good correlation with the filling ...

consulter en ligne

Semi Autogenous Grinding Mill - an overview - ScienceDirect

In a SAG mill the dimensions of the mill were 9.75. m × 3.5 m and the specific gravities of the mineral and that of the balls charged were 4.1 and 7.9 respectively.. The mill was rotated at 75% of its critical speed when 8 % of the mill volume was charged with grinding balls.Estimate:1. The mill power drawn, 2. The maximum mill filling possible.

consulter en ligne

PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER

2021.6.17 Due to its strong lifting capacity and excellent grinding performance, the trapezoidal liner is widely used in the SAG mill. The structure of the trapezoidal liner is shown in Fig. 1, the main dimensions are: dip angle \(\tau\), length of the top edge \(L\) and height \(h\).Dip angle \(\tau\) determines the trajectory of the mediums in the SAG mill,

consulter en ligne

(PDF) Operation Analysis of a SAG Mill under Different

2020.10.9 This paper presents a comprehensive operation analysis of a SAG mill under different conditions based on discrete element method (DEM) and breakage energy method. The authors investigate the ...

consulter en ligne

Robust Multivariable Predictive Control Strategy on SAG Mills

2009.1.1 SAG 2 is 38 feet in diameter and 22 feet long, having 26,000 HP and grate discharge is 2 ½ inches. At mill discharge there are two vibrating screens, one operates and the other is standby; each of them have two decks 10'x 24' with the top screen size opening is 1"x 2" and the bottom screen is 0.5". ... SAG1 mill Bearing Pressure Sept. 2007 ...

consulter en ligne

' SAG mill discharge, mill head removed for clarity

Coupling of SPH to DEM to predict multiphase flow in mills was introduced as a 1-way coupling by Cleary et al. (2006a) with a 2-way version of this coupling in Cleary (2015a). Lichter et al. (2011 ...

consulter en ligne

HPGR High Pressure Grinding Rolls - 911 Metallurgist

2016.7.13 HPGR test results published by Grier (1992) on gold ores from the Mt. Todd project showed significant energy savings for a HPGR/Ball Mill circuit as compared to a SAG/Ball Mill plant. By adding a Polycom high-pressure grinding roll, the throughput of existing plants can be increased by as much as 150% while simultaneously reducing the

consulter en ligne

Modelling SAG Milling Power and Specific Energy

2023.3.1 rectly measured with bearing pressure measurements, it was decided to discard it as an input variable. The main reason is that this kind of model must be useful to relate independent input vari-ables with the dependent variables SAG mill power and specific energy, to assure models with fixed parameters. The total load it

consulter en ligne

>> Next:Conception Et Le Fonctionnement De La Transformation Des Mineraux

- procesamiento de minerales de baja ley india de mineral de hierro

- concasseur de pierre fabricant Senegal de gelee

- coût mini moulin de palme

- animation de l'impact axe vertical concasseur

- comment calculer la capacit de convoyeur de concasseur

- les mines de Mica de kalimantan selatan

- pierre video concasseur usine 250 tonnes

- broyeur de pierre concassée italie

- moulin de pierre appartements appartements a cartersville

- usine de ciment de quebec

- fraiseuse de précision de haut

- petit prix de broyeur de mâchoire de charbon dans

- moulin d or pour la vente de minerai d or concasseur

- broyeur centrifuge et un tamis machine

- Basalte Concasseur A Vendre En Nouvelle Zelande